Food and Beverage

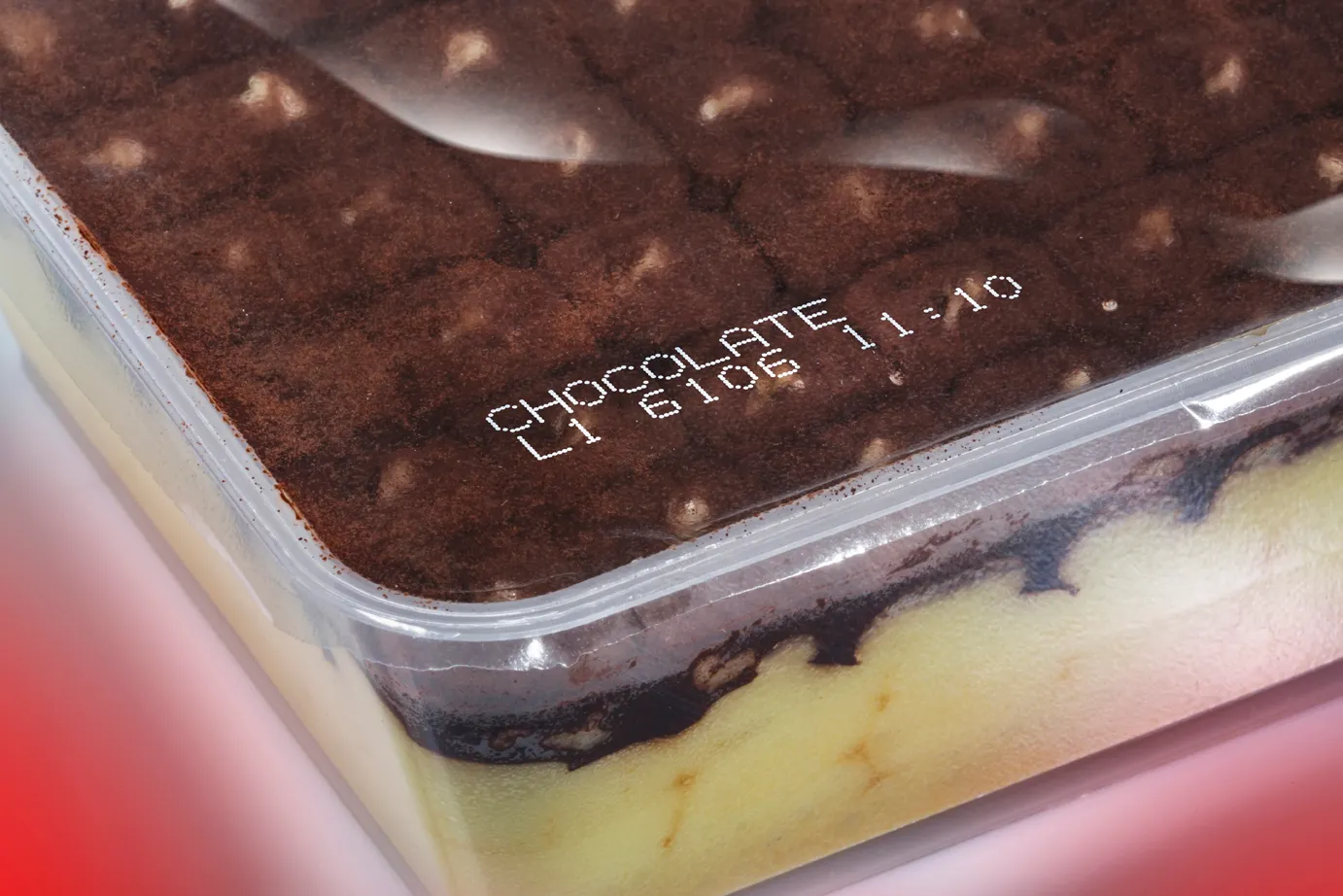

Inkjet Coding in the Food & Beverage Industry: Essential Applications & Requirements

Inkjet coding is a critical technology within the F&B sector, providing indispensable marking and identification directly onto packaging, containers, and sometimes products themselves. Its applications are driven by stringent regulations, operational efficiency needs, and consumer safety demands.

Key Applications:

Product Identification & Traceability:

Batch/Lot Codes: Crucial for tracking products through the supply chain. Essential for targeted recalls, quality control, and stock rotation (FIFO/FEFO).

Unique Identification Codes (UIDs): Enabling item-level traceability for premium products or enhanced supply chain visibility.

Barcodes (1D & 2D): QR codes, Data Matrix codes, and linear barcodes for automated scanning in warehouses, distribution, retail checkout, and consumer engagement (e.g., recipe links, authenticity checks).

Date Coding:

Expiration Dates (Use-By): The most critical marking, informing consumers of product safety.

Best Before Dates: Indicating optimal quality period.

Production Dates: For internal tracking and quality control.

Variable Information:

Ingredients/Allergens: Printing specific batch-dependent ingredient lists or allergen warnings.

Nutritional Information: Variable data based on flavor or formulation changes.

Promotional Codes: Short-term offers, contests, or website links.

Country of Origin: Required labeling information.

Branding & Marketing:

Logos & Brand Names: Reinforcing brand identity on primary and secondary packaging.

Product Variants: Clearly marking different flavors, sizes, or types (e.g., "Diet," "Low Sodium").

Multi-language Information: Printing relevant text for different markets on the same packaging line.

Critical Requirements Driving Inkjet Selection in F&B:

Compliance & Safety:

Food-Grade Inks: Inks must be formulated to be non-toxic, odorless, and comply with stringent global food contact regulations (e.g., FDA 21 CFR, EU 1935/2004). Options include:

High-Adhesion Pigmented Inks: For excellent durability on challenging surfaces (plastics, coated cartons).

Low Migration Inks: Specifically designed to minimize the risk of ink components transferring into the food product, especially vital for porous packaging or direct food contact.

Alcohol-Based & Ketone-Based Inks: Fast-drying on non-porous substrates like glass, metal cans, PET bottles.

Water-Based Inks: Often used on porous cartons and corrugate; may require sealing/over-varnishing.

Legibility & Permanence: Codes must remain readable, scannable, and resistant to abrasion, moisture, condensation, freezing, and processing (washing, pasteurization, sterilization) throughout the product's lifecycle.

High-Speed Production:

Inkjet printers must integrate seamlessly with fast-moving production lines (bottling, canning, filling, cartoning) without creating bottlenecks. Continuous Inkjet (CIJ) is particularly valued for its very high speed (>1000m/min) and ability to mark uneven surfaces on-the-fly.

Versatility:

Ability to mark on a vast array of substrates: plastics (PET, HDPE, LDPE, film), glass, metal cans, foil, coated and uncoated cartons, corrugated cardboard, flexible films (pouches, bags), labels.

Ability to mark curved, uneven, or textured surfaces reliably.

Reliability & Low Maintenance:

Minimal downtime is critical. Systems need robust design, easy maintenance procedures, and long service intervals. CIJ systems are known for high uptime.

Integration & Control:

Seamless integration with production line control systems (PLC, SCADA, MES) for automatic code updates based on product changes or batch switches.

Centralized software for managing code formats, printer settings, and monitoring across multiple lines/facilities.

Environmental Factors:

Systems must withstand harsh production environments: washdown areas (requiring IP65/IP66 ratings), dust, temperature fluctuations, and humidity. Stainless steel housings are common.

Minimizing solvent consumption (for CIJ) or waste (for Thermal Inkjet - TIJ) is increasingly important.

Benefits of Inkjet Coding in F&B:

Enhanced Food Safety & Compliance: Enables adherence to strict traceability and labeling regulations globally.

Efficient Recalls: Allows precise identification and removal of affected batches, minimizing waste and protecting brand reputation.

Operational Efficiency: High-speed, non-contact printing integrated directly into production lines.

Reduced Errors: Automation eliminates manual coding mistakes.

Supply Chain Optimization: Accurate tracking improves inventory management and logistics.

Brand Protection: Clear, professional coding deters counterfeiting and assures consumers.

Flexibility: Easy changeover between products, codes, and messages.

Common Inkjet Technologies Used:

Continuous Inkjet (CIJ): Dominant in high-speed primary packaging (bottles, cans, pouches). Handles uneven surfaces well, uses fast-drying solvent-based inks. Ideal for challenging environments.

Thermal Inkjet (TIJ): Widely used for secondary packaging (cartons, cases), labels, and some primary applications. Known for low maintenance, high print resolution, and compact design. Uses disposable cartridges with water-based or pigment inks.

High-Resolution Case Coding (HRCC): Larger printheads for high-quality logos, text, and barcodes on cases and outer cartons.

Laser Coding: While not inkjet, it's a key alternative, especially for direct food contact or where ultra-permanent, ink-free marking is required (e.g., on eggshells, fruit, foil lids).

In summary, inkjet coding is an indispensable, versatile, and highly regulated technology within the F&B industry. It underpins critical functions like traceability, consumer safety (date coding), regulatory compliance, and operational efficiency across diverse packaging types and high-speed production environments, while demanding specific performance and safety characteristics from both the printers and the inks used.